Sand Dual Filters

STEADY SAND FILTER - DUAL MODEL

Double chamber steady sand or grit filtering system

|

Funzionamento in filtrazione »

Codice e portata Dual manuali »

|

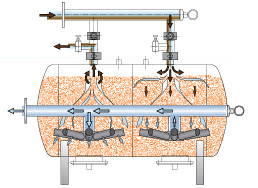

Peculiar filtration requirements for waters designated to irrigation or micro-irrigation in agriculture need systems using quartzite layers. Basically it is the same natural process of water that goes through the ground layers before reaching the underground flap. The substantial difference with respect to the vertical model Arena is the presence of the double filtration chamber that enables the single filter to filtrate in a continuous way, also during back washing that takes place in a chamber at a time. Available in the following versions:

Models:

In the manual models it is necessary to integrate a back washing kit equipped with shutter valves. These version allow low cost purchase but request a constant maintenance for the back-washing.

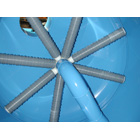

In the automatic versions the continuous operation is assured by valves automatism. The valves are controlled by a programmable control box. Both filters and support-frame are completely made of painted or zinc-coated steel. In the lower inside part of the chambers Dual Filters are equipped with filtering arms with 0,25 mm nozzles through which water flows outside perfectly filtered. Applications

Being this a static drop filtration system, it is suitable to any kind of filtration of waters coming from:

Ideal for usage in agriculture (irrigation system)

Filtration rate:

It equals a filtration rate of: 100 µ.

It assures the trapping of very small particles such as:

It is advisable to mount upstream, a pre-filter such a Hydrocyclone that can remove up to 90% sand and solid particles or a screen filter. Operation during filtration:

The water to be filtered forcedly enters from the upper part (maximum working pressure 8 bar) and falls on the grit layer inside the two chambers... »(enter)

Back-washing:

Over time filtration becomes less efficient and flow rate loss in outlet may occur (or loss of load)... »(enter)

Maintenance:

If properly used and dimensioned, maintenance is basically null.The forced back-washing system cleans and re-generates the grit layer which, besides, over time, needs to be replaced. Total grit replacement frequency depend on the filter usage conditions and on the kind of water to be filtered. Grit replacement

We normally advice grit complete replacement every 4-5 years because over time grit tends to get round by smoothing consequently blocking the micro-holes of the filtering arms placed at the bottom (flow rate decrease).

Versions, part numbers, flow rates

|

Clicca sulle frecce per scorrere le immagini

Immagini:

Send your request!

Send your request!

Hai bisogno di un´┐Żapplicazione

per un impianto particolare?

Vuoi un filtro "su misura"?

« Enter »

l’efficienza negli impianti

di irrigazione e microirrigazione

>> (entra)

La filtrazione

>> (entra)

Brevetti

>> (entra)

Il riutilizzo dell'acqua

>> (entra)

Via Emilia n° 51/E 40011- Anzola dell’Emilia (Bologna) - Italy

Tel.: +39 (051) 73.21.90 - info@omparenti.com

P.IVA e C.F.: 02577301209 NUMERO REA: BO - 450522 ISCRITTA NELLA SEZIONE ORDINARIA IL 03/08/05

CAPITALE SOCIALE VERSATO : € 10.000,00 €